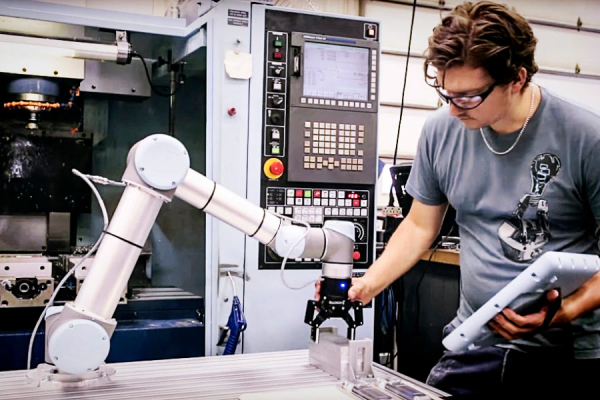

Robots have always played an important role in the automotive industry. With the changing and demanding technology, it has given rise to the new features in the automobile industry. The vehicle parts are increasing day by day and so is their demand. At present, the demand for the manufacturing of automobiles is increasingly becoming very important and the costs are also becoming high. Witnessing the high demand in the automotive industry, cobots or collaborative robots are now being used to avoid human errors. It has also helped in increasing productivity and precision.

They are now used along with the humans in automotive manufacturing to aid the humans in increasing the productivity level and help them in other related work. The robots are built easily while taking care of the human’s safety features as well.

To make it more accessible for the collaborative and robotics solutions, many manufacturers in the robotic industry have come with a service policy. It presents great accessibility to the cost-sensitive and start-up industries. The manufacturers have reduced the entry barrier, thus making the robotics solution easy and accessible. This is a great step to introduce robot service in the economy to help humans.

The automotive industry is witnessing huge change and the demand for automobiles is also increasing at a great speed. This is mainly affected by the manufacturers and the suppliers of the cars, where they will always have to be prepared for the demand-supply.

The Future Factory – Mobile, Modular and Flexibility

One of the finest examples of the future factory is Audi. They have adopted a modular and mobile assembly approach to come up with the demands of the product varieties and to continue to integrate the new process in the production. The AGVs – Automated Guided Vehicles, lightweight and flexible robots from the Universal Robots also known to play a vital role in the Audi factory.

Check Out – Tha latest updates about collaborative robots in the automobile industry.

Leave the Unfavorable and Ergonomically Tasks to the Cobots

Flexibility is very important in the manufacturing industry. This is the reason collaborative robots are used in the automotive industry. Human employees are exposed to activities that are very hard and also affect their health. Hence, to ease the burden from humans, cobots are used to complete strenuous tasks.

This was recognized by the Bajaj Automobile company long back. They witnessed the stress and the workload given to their employees for the demand for meeting the production was way too high. It was becoming increasingly difficult for human employees to handle the workload pressure. It also demanded perfection and speed. It was then they decided to introduce cobots in the production to ease the pressure from the human employees. The cobots helped the humans in not only bringing out the perfect quality products, but the task was completed much faster too.

A similar case was witnessed in the Nissan Motor Company too. With the increasing demand, it became difficult for the company to manage the challenge. With the introduction of cobots, the company solved almost all the problems making the employees happy and satisfied. The workload and the heavy lifting job were now eased, all thanks to the cobots.

The cobots are not just used in huge multinational companies. They are used even in small companies too to aid human employees. With the introduction of cobots in the industry, it not only saves time, labor and money, but also the work is done at a much faster rate. The quality is also improved as one cannot expect humans to proffer the same quality work to all the provided tasks. With the increasing demand in the market, the companies can now confidently meet the required demands with much ease. They will no longer have to be completely dependent on humans for all the tasks.

Hence, with the introduction of collaborative robots in the industry, the workload for humans has decreased. The industry also now enjoys all the flexibility and great work quality. Seeing the demands for the cobots, they will now be soon employed in all sectors of the industry as well.