What Is Injection Molding?

Injection molding is a manufacturing process in which molten plastics are mold cavities to create plastic parts. Once the melted plastic becomes hard, the plastic parts manufacturers in India extracts the finished part. Plasticmolding companies consider injection molding a reliable method, as it helps produce high-quality solid plastic parts by investing less capital. Many companies use the injection molding process to succeed in their business, and one such industry is the automotive industry.

How Can Injection Molding Help Automotive Industry?

Here are the reasons why the injection molding process plays a major role in the automotive industry.

- Repeatability

The ability to produce identical parts continuously or repeatably is a crucial factor in the automotive industry. The automotive industry typically relies on strong metal molds, and most of the finished parts will be identical. Since the plastic injection molding process is highly repeatable, the manufacturers can continuously produce identical plastic parts with perfect design and finishing.

- Material Availability

One of the major benefits of using plastic injection molding in the automotive industry is that the process is compatible with various types of flexible, rigid, and rubber plastics. The manufacturers in the automotive industry prefer to use different polymers for various applications, including acrylic, polypropylene, acetal, ABS, polycarbonate, nylon, etc.

- Scale And Cost

The cost of the mold makes the injection molding process quite expensive. However, it is a scalable process as there will be a reduction in the overall costs when the manufacturers create more parts. Since the injection molding process is highly efficient in producing parts in high volumes, it remains beneficial to the automotive manufacturer.

- High Accuracy And Surface Finish

It is quite easy to produce parts with simple geometries with the injection molding process as it gives a good surface finish quality. There are many finish options for the manufacturer when producing parts with various surface textures like rough, matte, or glossy. The manufacturers directly apply these textures to the mold instead of the finished molded part.

- Color Options

With plastic injection molding in the automotive industry, it is quite easy to change the color of the automotive parts according to the vehicle’s color. The injection molding processes allow mixing the dyes with the raw materials before beginning the manufacturing process. This process creates sold and consistent coloration so the manufacturers can avoid the need for painting once the molding is finished.

- Less Total Weight

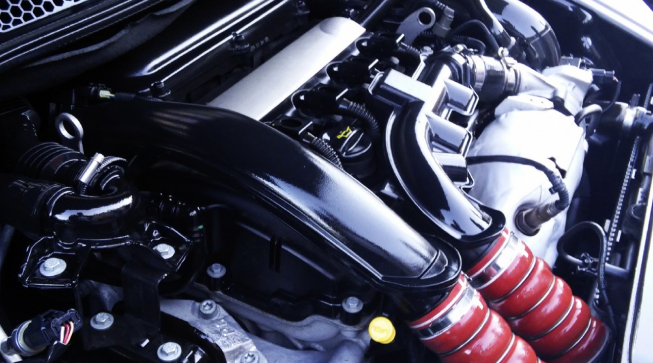

To increase the vehicle’s fuel efficiency, the best option is to reduce its overall weight other than making adjustments with the power. With plastic injection molding, manufacturers can achieve this goal by producing lightweight parts. These parts can replace the aluminium and heavier steel components. These days, many engine parts are made with plastic injection molding that even the heavy cargo vehicles weight is dropping.

- Fast Prototypes

Usually, in the automotive industry, manufacturers prefer to use injection molding for producing parts in huge volumes. Apart from that, the process can also be used as a prototyping tool. The manufacturers can create fast, low-cost aluminium molds by CNC machining or additive manufacturing, and they can make prototype molded car components faster than the traditional tooling.

- Creates Various Interior And Engine Parts

As an automotive manufacturer, you can improve the process and will be able to control the costs if you get a good percentage of automotive parts from the same supplier with plastic injection molding. Because plastic injection molding is used in creating many different parts of even modern vehicles, you can order in bulk from the plastic injection molding subcontractors.

- Finer Details

Plastic injection molding is the best process for producing parts with high tolerances, and there are very low chances of errors. A minor error can lead to fuel or oil loss that can be dangerous to the vehicle with other processes. Plastic injection molding is considered a no-error process as it can produce high-quality parts.

The automotive industry can get so many benefits from the plastic injection molding process in the future as every time there is an advancement in technology, it can make the injection molding processes much better. Read More